Behind the Scenes of Console Manufacturing

23 August 2025

Gamers often rave about the latest console graphics, gameplay experience, and hardware specs — but have you ever stopped to wonder how your favorite gaming console is actually made? We’re talking nuts, bolts, chips, plastics, and countless hours of blood, sweat, and silicon. Console manufacturing is a bit like making magic behind the curtain — it’s complex, secretive, and full of moving parts (literally).

Let’s take a deep dive behind the scenes of console manufacturing — how your PlayStation, Xbox, or Nintendo Switch goes from a wild idea at a meeting table to a shiny piece of tech sitting under your TV.

The Birth of a Console Idea

Every legendary console starts with a simple question: _“What do gamers want next?”_ This is where innovation kicks in. Console manufacturers — think Sony, Microsoft, and Nintendo — pour millions into market research and gaming technology trends.They’re not just chasing better graphics or faster load times. They’re looking at how people _use_ consoles. Are players streaming more? Do they crave portability? Are motion or VR features a must-have?

Once they pin down the direction, designers and engineers team up to brainstorm the console's blueprint from scratch. Think of it like baking a cake — but this one needs to run 4K games at 60 FPS and stream Netflix at the same time.

Mapping Out the Hardware: Design Meets Function

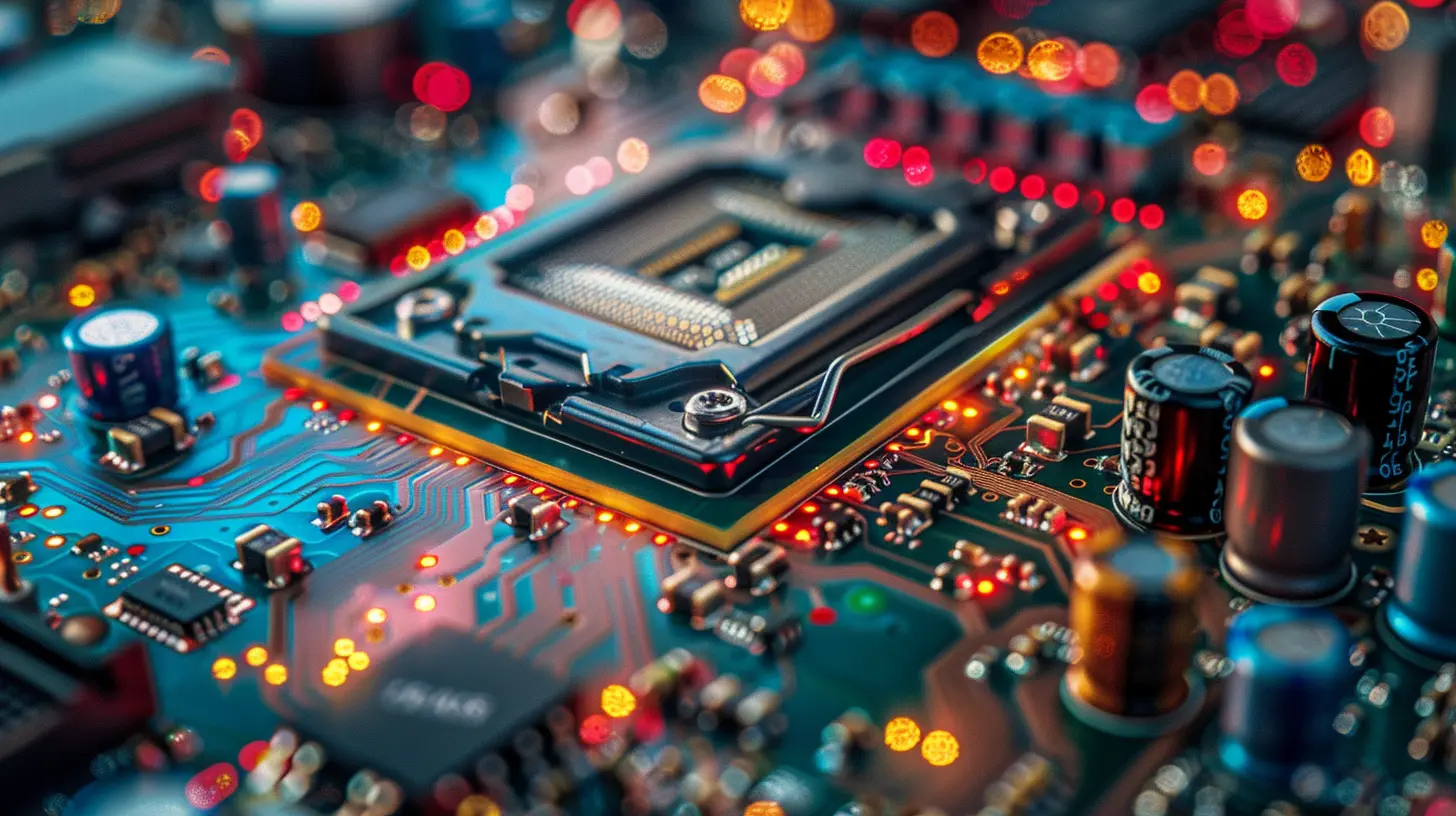

When the concept is locked in, the real nerdy stuff begins.1. Choosing the Right Components

You might think a console is just a mini PC, but it’s not that simple. Console manufacturers work closely with chipmakers like AMD and NVIDIA to build custom processors and graphics units.They need to balance price, power, and performance. If it’s too powerful, it gets expensive. If it’s too cheap, it’s... well, a disappointment. That’s why each component — from the CPU and GPU to the RAM and storage — is hand-picked and optimized to work together.

2. Prototyping the Magic Box

Have you ever wondered why consoles look the way they do? It’s not just aesthetics — though sleek designs definitely help people fall in love with them. The design has to consider airflow (so it doesn’t overheat), internal space for the hardware, and even how easily technicians can assemble and repair it.Engineers create multiple prototypes using 3D printers and CAD software. They tinker, test, and tweak — sometimes for months — before settling on "The One."

Building the Console: From Factory Floor to Finish Line

So now that the design’s finalized and parts have been selected, the manufacturing journey begins. Ready for a trip to the assembly line?3. Sourcing the Components

First things first, those individual chips, circuit boards, plastic shells, and screws need to come from somewhere. Console makers have a vast global supply chain — parts might come from Japan, China, Germany, or the U.S.This is where the strategy gets critical. A shortage of one tiny component (like a semiconductor) can delay the entire production line — remember the console shortages in 2020 and 2021? Yep, that’s why.

4. Assembly Line Action

The heart of console manufacturing happens in massive facilities — mostly in countries like China, Taiwan, and sometimes Mexico or Eastern Europe. These factories are highly automated but still rely on skilled workers for assembly tasks that machines can’t handle precisely.It goes something like this:

- The motherboard (the brain of the console) is assembled first, with chips and modules soldered precisely.

- The cooling and heat management systems are added, including fans, heat sinks, and thermal paste.

- Next up: storage drives, optical drives (if needed), and wireless modules are installed.

- Everything is fitted into the carefully designed plastic shell.

- Controllers are manufactured alongside or separately, with overlapping processes.

Every unit goes through rigorous testing — thermal checks, software boots, performance benchmarks, and even drop tests. If a unit fails? It’s pulled aside, diagnosed, and fixed before it can be boxed.

Quality Control: Zero Room for Error

Let’s be honest — gamers don’t go easy on console makers. If there’s a glitch, lag, overheating issue, or loud fan noises, it’s all over Reddit in seconds.That’s why quality testing is taken dead seriously.

Before a console gets shipped, it goes through multiple stages of quality control:

- Burn-in Tests – Consoles are turned on and left running for hours to catch hardware failures.

- Signal Tests – Engineers verify HDMI outputs and audio signals are crisp and clean.

- Stress Tests – Consoles are pushed to their limits to ensure they can run the most demanding titles.

- Compliance Tests – It’s also checked for electromagnetic interference and safety certifications.

Basically, they do everything except drop it from a rooftop — though that might not be far off.

Packaging and Shipping: Ready for Launch Day

Ah, the finish line. Boxes are printed, manuals are inserted, and the shiny new consoles are packaged with their accessories. It's like wrapping a birthday gift for millions of people at once.But even boxing isn't simple.

Console makers design eco-friendly, damage-resistant packaging that also shows off the product. It's marketing and protection rolled into one tidy box. Talk about multitasking.

From there, consoles are shipped globally — by air, sea, rail, or truck — to warehouses, retailers, and, eventually, your local game store or the front porch if you ordered online.

Sustainability in Console Manufacturing

Let’s get real: building electronics isn't exactly kind to the environment. With growing awareness, console makers are starting to go green.5. Recycling and Reducing Waste

Companies are using more recycled plastics, reducing packaging materials, and working on more efficient power usage. Microsoft even committed to making the Xbox Series X more energy-efficient and carbon neutral over time.6. Ethical Sourcing

There are also efforts to ensure “conflict-free” minerals (like gold, tin, and cobalt) are used to prevent exploitation. It’s not perfect yet — but it’s improving.The Human Side of Console Production

Behind every console lies a workforce of thousands — from engineers and designers to factory line workers. It’s important to acknowledge that real people are behind that screen you’re gaming on.Some companies are taking steps to improve working conditions in manufacturing plants. Others are facing pressure to do more. The gaming community plays a role here too — our buying decisions and voices can push companies toward better labor standards.

The Economics of Console Manufacturing

Here’s a surprising truth: Console companies often lose money on hardware at launch.Wait, what?

Yep. The PS5 and Xbox Series X were sold at or below cost for a while. So how do companies survive? Games and subscriptions, baby. When you buy a game, a controller, or subscribe to Game Pass or PS Plus — that’s where the money comes in.

It’s like selling a printer at a loss and making the profit on the ink. Smart, huh?

Future of Console Manufacturing

With cloud gaming, AI-driven chips, and modular designs, the next decade of console manufacturing is going to get wildly innovative.Don’t be surprised if consoles become way smaller, quieter, or even disappear. Imagine a tiny console that streams games directly from the cloud. Or a modular console where you upgrade only the GPU, sort of like a gaming PC.

Crazy? Maybe. But 10 years ago, so was the idea of playing top-tier games on your phone or getting games via subscription.

Final Thoughts

The next time you power up your console, think about the journey it took to get to your entertainment center. From whiteboard sketches to factory floor magic, console manufacturing is a stunning blend of tech, creativity, logistics, and human labor.It's not just about pressing buttons. It's about building a gateway to countless hours of joy, competition, stories, and memories.

So yeah, there's a whole world behind that sleek box of wonders — and it’s more epic than most video game plots.

all images in this post were generated using AI tools

Category:

Game ConsolesAuthor:

Kaitlyn Pace

Discussion

rate this article

1 comments

Lena Nelson

Who knew crafting consoles involved more drama than a reality show? Can we get a behind-the-scenes pass for the next season?

September 9, 2025 at 4:56 AM

Kaitlyn Pace

Absolutely! The behind-the-scenes of console manufacturing is full of twists and turns that rival any reality show. Stay tuned for more insights!